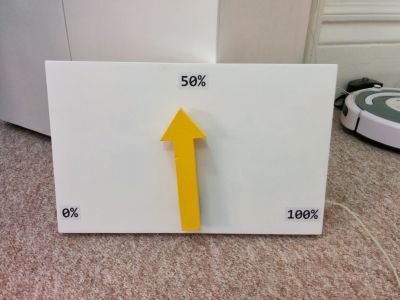

Gauge Display

Over the past year or two I have done some work setting up dashboards and whilst they can be really cool the displays get a little dull over time. With this in mind I started work on a physical status gauge, something that would be more interesting to look at.

The status gauge I chose to replicate was a gauge style meter, mainly because this seemed the easiest! Rather than dealing with linear movement for a bar graph a gauge uses a rotating arm which could be implemented with a single servo. After coming up with the idea I was able to build the bulk of it using resources I already had, you can read about this in a previous post about my workshop. This initial gauge worked and it looked alright; it did appear a little amateurish but this was something I was initially going for. The main issue was that it looked boring!

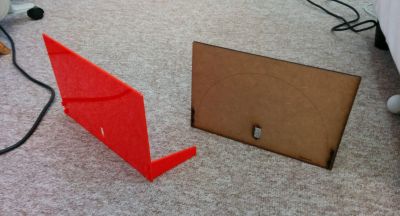

I have access to a laser cutter at Build Brighton so I decided to build a second one out of acrylic. This would be a smaller unit as the overall size was determined by the cutting area. I came up with a rough design in DraftSight, (BTW this is the best software for making accurate 2d designs I have found so far) and I borrowed some acrylic and cut the first design. This was really effective and worked well so I ordered a couple of sheets of acrylic including a frosted white one as well as some mdf for cheap prototyping.

In the first version of the frosted acrylic gauge I taped the led strip to the back of the plastic, this worked well but the tape could be seen from the front and didn't look very good, this problem was going to apply to anything pressed against the surface. Because of this I came up with the sandwich design with the middle layer having a cutout for the lights to sit in, this way the only thing visible from the front is the cutout and because that follows the arc of the arrow it looks like it should be there.

Like the status light the electronics are basically the same, an electric imp, trinket, neopixel strip and a servo; the servo bolts into the middle and the electronics mount to the back in a 3d printed case.

This build took a little longer than I had planned for but that was because of a few design decisions which took a while to make. The latest gauge design can be built fairly quickly, the longest bit comes from turning the straight neopixel strip into a curved one which involved cutting it at each break point and re-soldering at an angle. Like all projects there are a few improvements that can be made but otherwise it is a complete project.